XRC 100-100DV | LARGE PARCEL AND FREIGHT

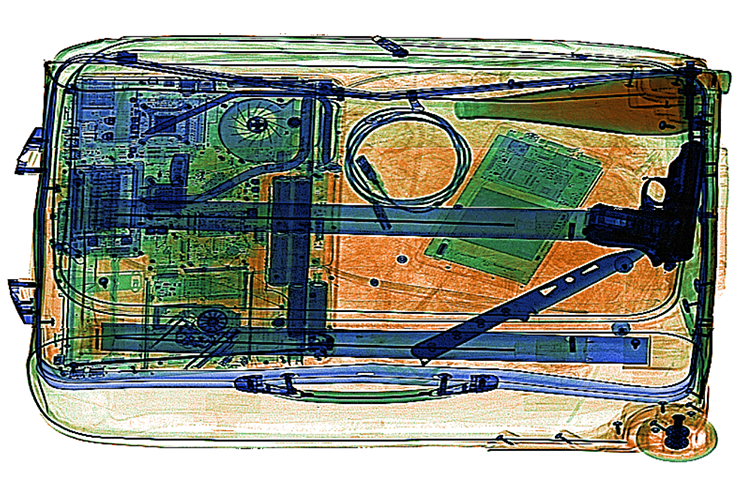

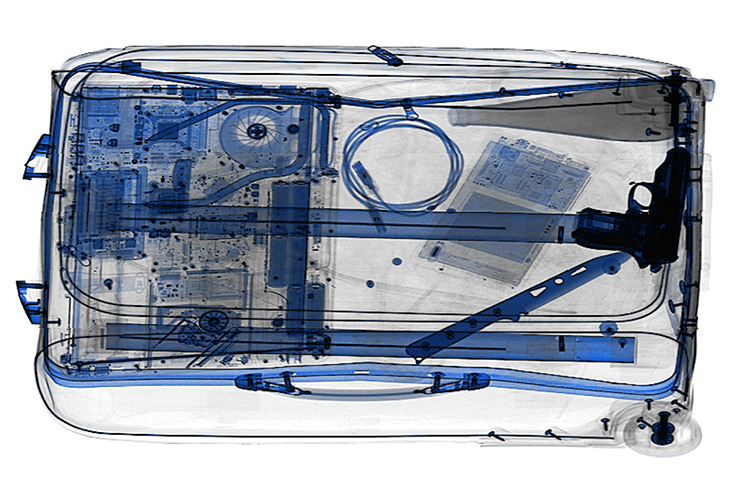

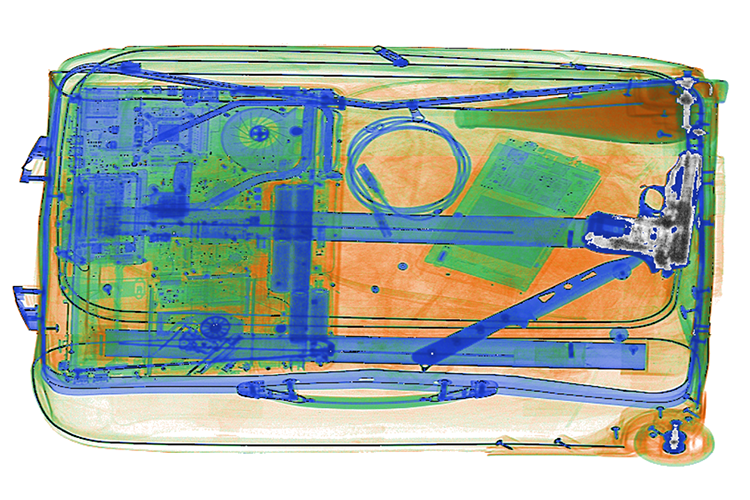

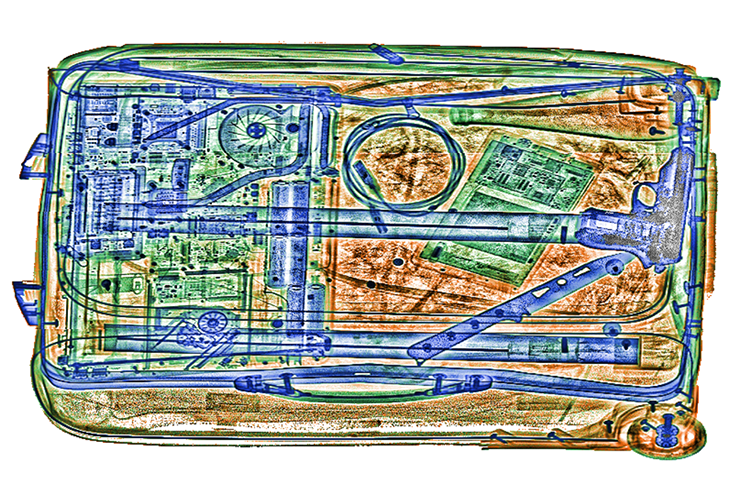

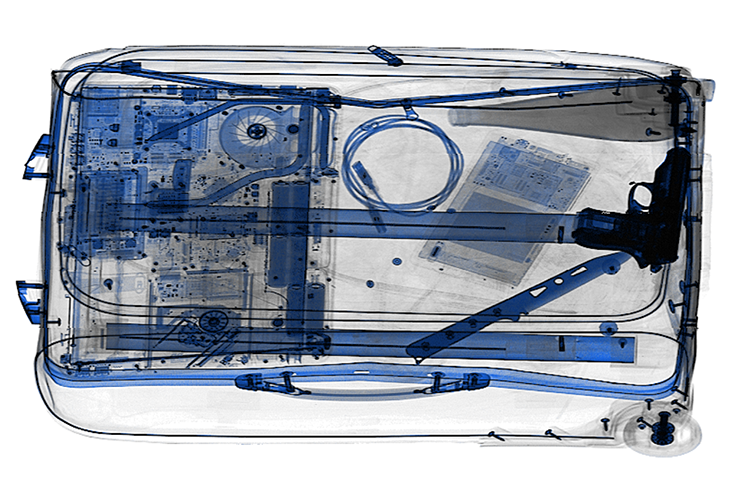

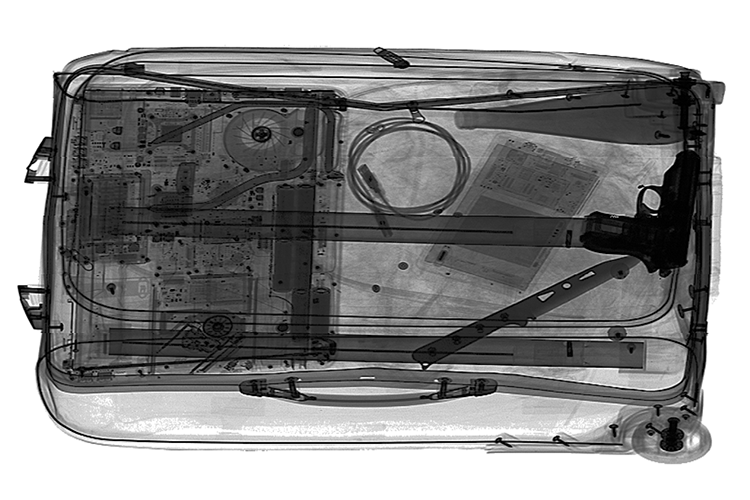

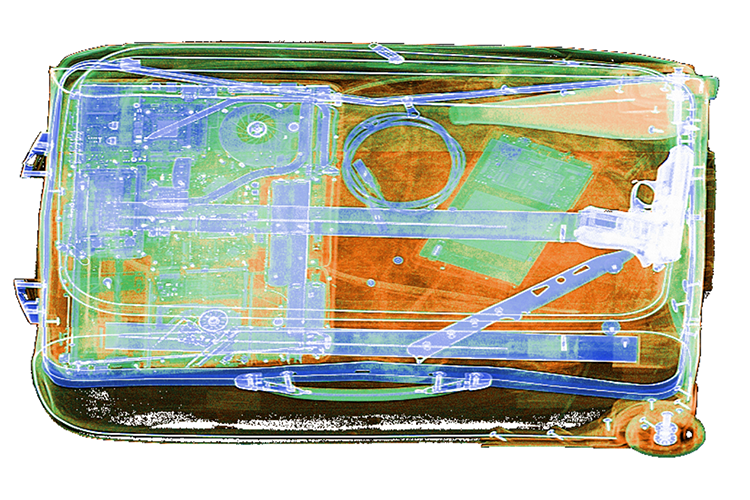

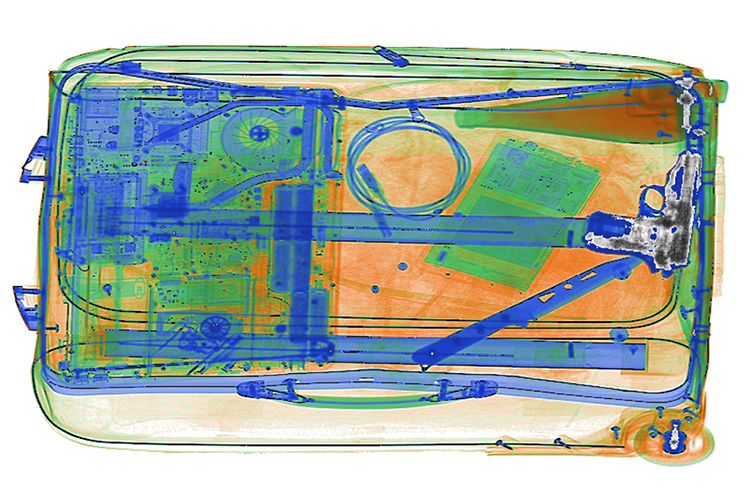

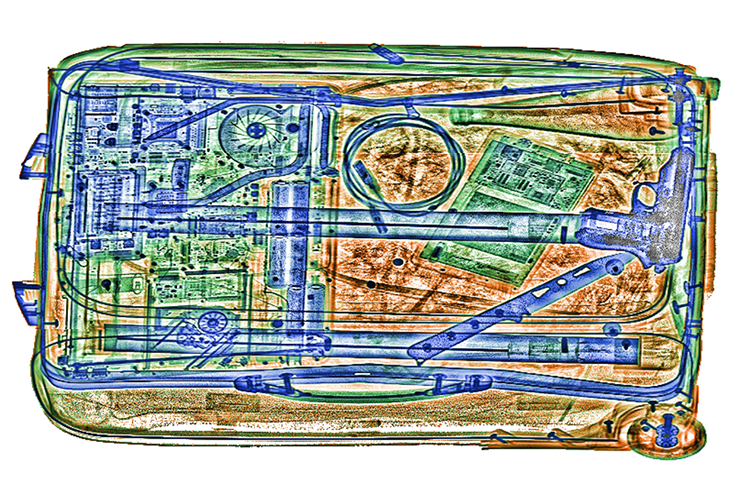

American Transportation Security Administration (TSA) ACSTL certified XRC 100-100DV x-ray baggage scanner facilitates the operators use thanks to the various image processing functions, hazard alarm, advanced computer technology and the best in class software. It enables easy identification of potentially threatening objects such as cutting tools, explosives narcotics and minimizes the error rate. Thanks to its multi-diode structure and quality in imaging of scanned materials, image is colored based on density and shows organic, inorganic and mixed materials in different tones.

It is designed/manufactured with dual view (DV) technology. Thanks to its 2 x-ray generator sources, it provides high resolution and detailed imaging in horizontal and vertical angles. The images can be accessed with a single scan without the need to re-place the packages in a different orientation. Thus, hidden objects in the luggage are detected more easily and quickly.

It is an efficient and a powerful device for scanning medium and large bags and packages in detail. The x-ray security machine provides the ideal solution for locations where security screening is required like at high traffic checkpoints as city transportation (metro, ferry, train stations), customs border crossings, prisons, and courier depots, like international logistics companies, goods acceptance points and etc.

FEATURES & SPECIFICATIONS

- PROGRAMMABLE FUNCTION KEYS PARCEL COUNTER

- DATE AND TIME DISPLAY

- VIRTUAL THREAT IMAGE PROJECTION (TIP)

- ORGANIC/INORGANIC THREAT ALARM OPERATOR

- TRAINING PROGRAM (OTP)

- UPS (FOR COMPUTER SUPPLY)

- MULTI LANGUAGES

- SELF DIAGNOSIS

- GENERATOR TIMER AUTOMATIC STOP CONVEYOR

- BARCODE READER SYSTEM

- EXTERNAL CAMERA ARCHIVING

- REMOTE VIEWING STATION

- RECHECK STATION

- NETWORK SUPERVISORY SYSTEM (NSS)

- REMOTE ACCESS CONNECTION

- SMART CARD LOGIN

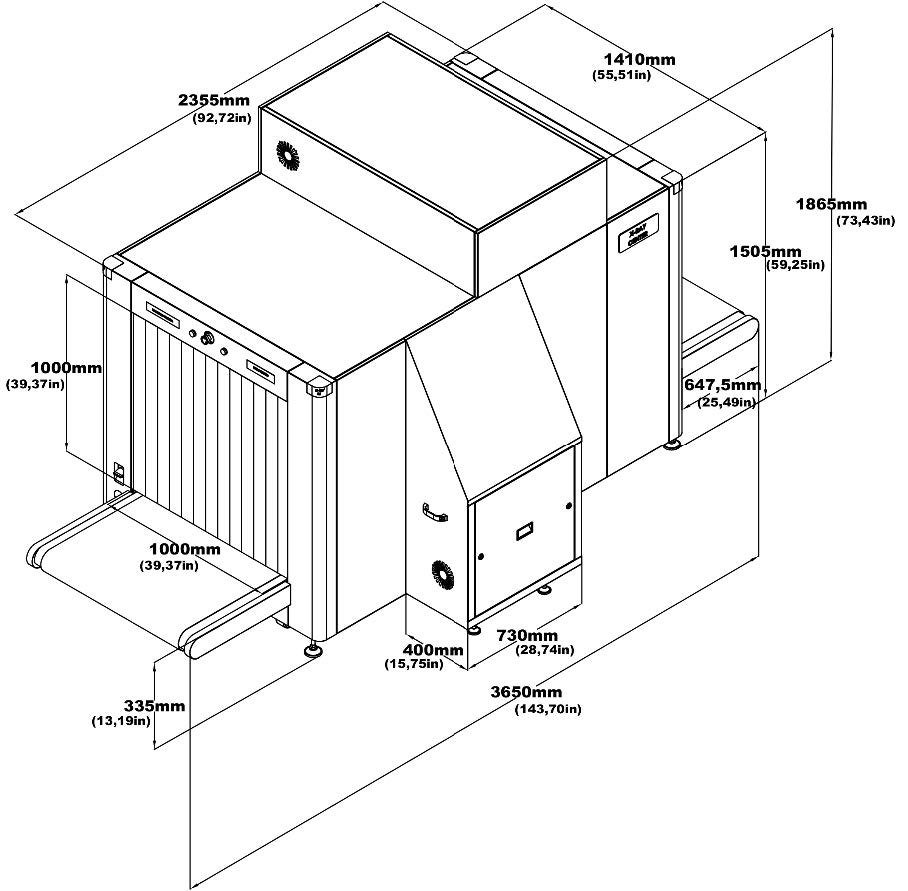

TUNNEL SIZE: 1,000 mm x 1,000 mm

DIMENSIONS: 3,650 mm x 1,865 mm x 1,810 mm

APPROX. WEIGHT UNPACKED: ~1,340 kg

CONVEYOR HEIGHT: 335 mm

CONVEYOR LOAD CAPACITY: 200 kg Evenly Distributed

SYSTEM POWER: 110/220V AC ± 10% 50/60 Hz, 5amp max.

CONVEYOR SPEED: 0.20 m/sec. Forward or Reverse

STEEL PENETRATION: 36 mm guaranteed; 40 mm typical

WIRE RESOLUTION: 38 AWG guaranteed; 40 AWG typical

ANODE VOLTAGE: 180 kV, operating at 165 kV

TUBE CURRENT: 1.0 mA

BEAM DIRECTION: 1st Generator: Vertically downward | 2nd Generator: Horizontally sideward

ARTICLE SEPARATION: Low Z, Medium Z, High Z to 0.5 Z Accuracy, Organic, InOrganic, Metallic

COOLING: Oil and forced air cooling

PROCESSOR: Intel® Core™ i5 (or superior)

MONITOR: 21.5” Flat (or superior)

MEMORY: 4 GB RAM (or superior)

VIDEO CARD: 2 GB (or superior)

HARD DRIVE: 1 TB (or superior)

USB PORT: 6 port (or superior)

OPERATING SYSTEM: Linux

MAIN FUNCTIONS OF IMAGE POST-PROCESSING

OPTIONAL ACCESSORIES

OPEN-CLOSED OPERATOR CONSOLE

I-STAND OPERATOR CONSOLE

21,5‘’- 27’’ FLAT MONITOR

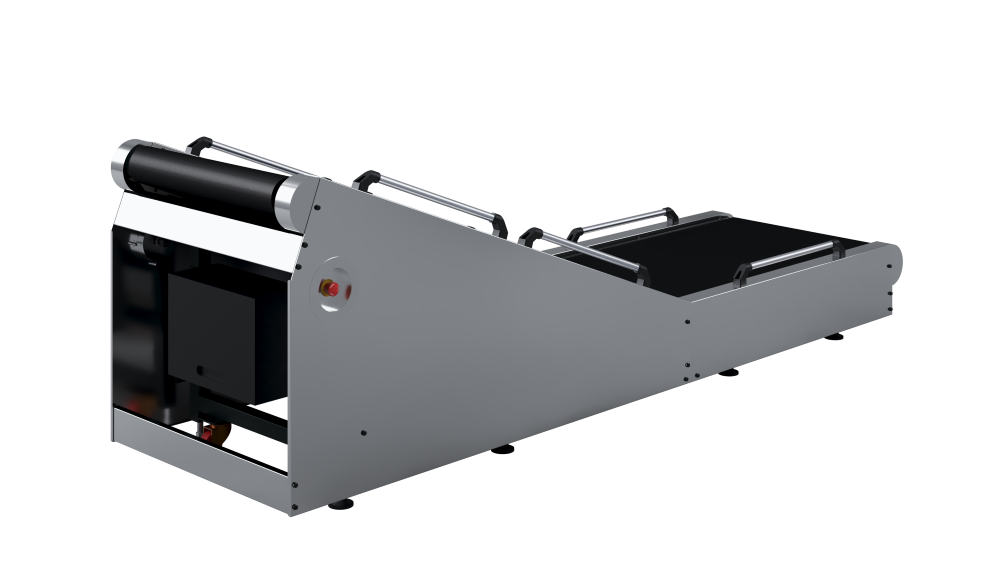

INCLINED CONVEYOR

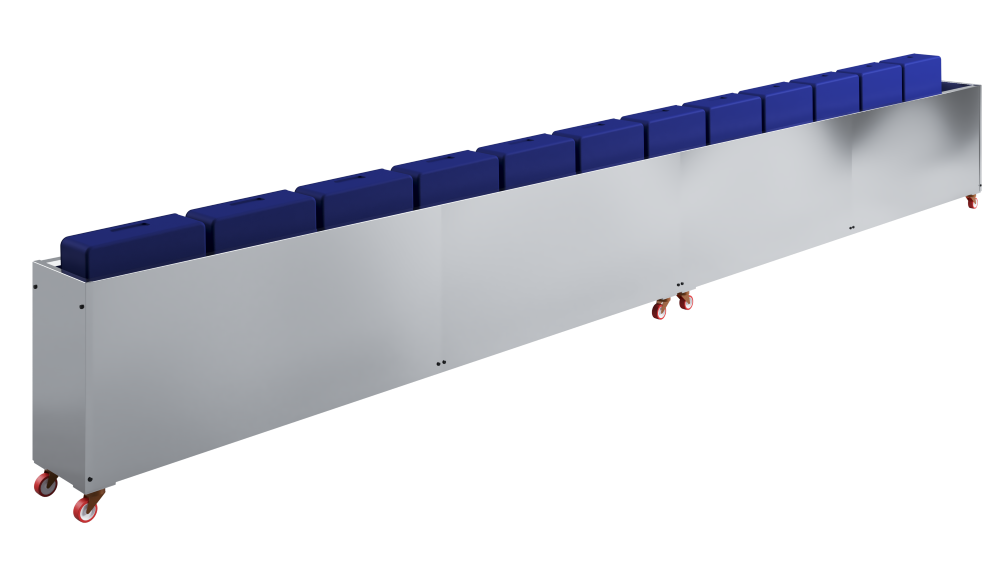

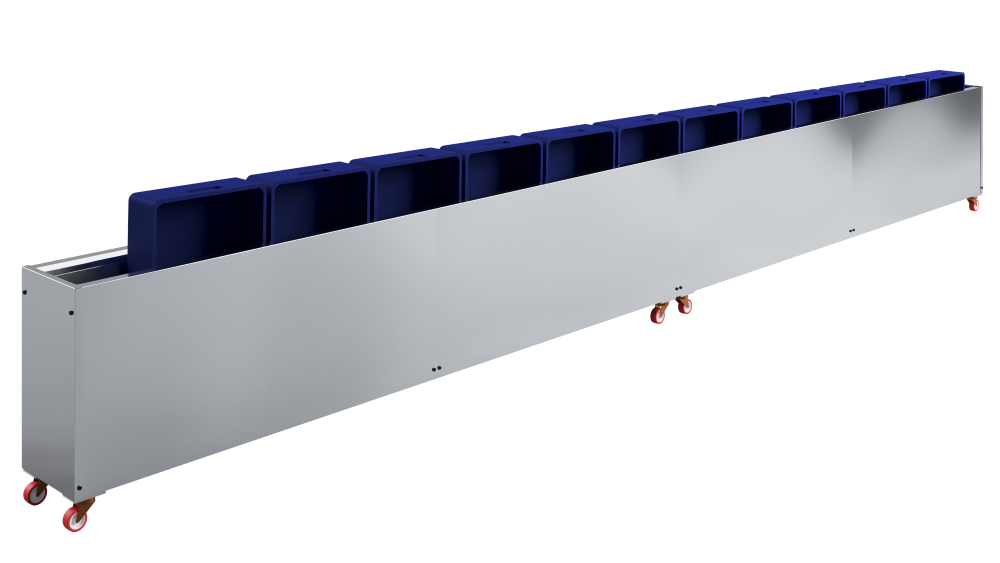

INPUT / OUTPUT ROLLERS

TRAY RETURN SYSTEM (MOTORIZED/GRAVITY)

SEARCH TABLE

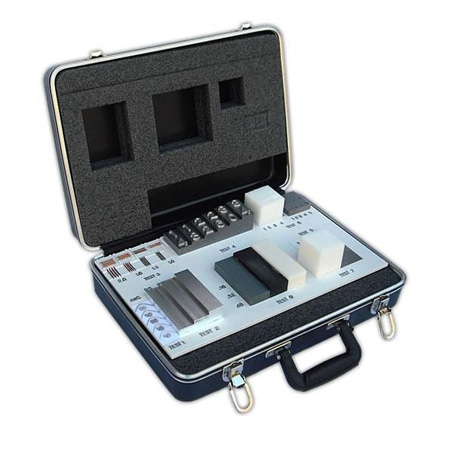

TEST KIT (STP/ASTM)